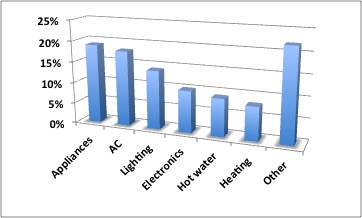

Thanks to Energy Star, Unites States is making its slow migration from the incandescent light bulb to LED lighting with an intermediate stop at CFL. Incandescent light bulb produces light with a wire filament heated with an electric current. In 1,880, the filament in Thomas Edison’s incandescent light bulb lasted 1,200 hours while 95% of the energy went to producing heat instead of visible light. After 135 years, it still does the same wasteful thing. In contrast, Compact Fluorescent Lighting (CFL) lasts 8,000 hours and produces the same amount of visible light with 25% of the energy expended by an incandescent light albeit with the necessity of mercury recycling. Light Emitting Diodes (LED) lighting lasts a whopping 50,000 hours and produces the same amount of visible light with only 10% of the energy expended by an incandescent light. As with every energy saving choice, the up front cost of an LED light is higher although the operating cost of an LED light is 10% of an incandescent light. The savings is not trivial as according U.S. Energy Information Administration lighting consumes 14% of the electricity in a typical American home.

The Energy Independence and Security Act of 2007 (EISA) set energy efficiency standards for light bulbs. Under the new law, household light bulbs will use at least 27% less energy by 2014 for a similar lumen output. The standards are technology neutral, which means any type of bulb can be sold as long as it meets the efficiency requirements. In fact, a number of manufacturers met the law by replacing the filament in the Edison light bulb with a halogen element. Given the performance we are going after in the Lily Pond House, we set out to eliminate not only the incandescent and CFL light fixtures but also the Thomas Edison era screw sockets by ensuring only LED lights can be used throughout the house.

Lily Pond House lighting was designed by Wiebke Theodore with a valuable assist on lighting fixtures by Greg Day Lighting. In selecting fixtures, especially for recessed lights, Insulation Contact (IC) rated new construction housings are attached to the ceiling supports before the ceiling surface is installed. IC housings must be installed wherever insulation will be in direct contact with the housing. The housing needs to be Air Tight (AT), which means it will not allow air to escape into the ceiling, thus reducing both heating and cooling costs. Unless you take care, some of these IC units are huge, taking valuable insulation space. For the recessed lights, we considered WAC and twicebright, and chose twicebright because the WAC option with its 0.9 cu ft volume took more than 10 times the volume of the twicebright option that took only 0.08 cu ft:

As with most green products, the origin of the space saving twicebright offering is from outside of USA. This company brings Scandinavian lighting innovations to the North American market. When you get rid of the Edison era screw base, you get the bi-pin base invented by Reginald Fessenden for the 1893 World’s Fair in Chicago. The International Electrotechnical Commission (IEC) periodically updates the bi-pin standards. GU10 10 mm twist-lock bi-pin for the MR16 light bulb in twicebright fixture has been around since mid-2000s. As a historical note Westinghouse won the contract to wire the first electrified fair with Tesla’s Alternating Current (AC) against Thomas Edison’s Direct Current (DC), and invented the bi-pin base because Edison’s General Electric company refused to allow his patented screw-base bulbs to be used.

120 volts of AC line voltage needs to be transformed into 12V or 24V DC for LED lighting. There are two kinds of transformers for this purpose: Large and heavy Magnetic Low Voltage (MLV) transformers, and small and light Electronic Low Voltage (ELV) transformers that are typically enclosed in the lighting fixture rather than hidden somewhere by the electrician. Magnetic transformers generate a low frequency hum while electronic transformers are virtually silent. It is ironic that more and more of the electronic equipment and lighting in our homes (e.g. laptops, phones, LED lights, etc.) run on DC power while the electricity is distributed by AC, necessitating the distribution of dozens of AC/DC transformers around the house. As a case in point, our design called for dado StepLine LED lighting that fits into the thickness of drywall. However, its installation requires running wires to a remote transformer, a hassle after the plaster is done. So we ended up going with WAC LED200 that is an integrated design that fits into a standard junction box.

- WAC LEDme Step Light

- dado StepLine LED

For Lilly Pond House, we have about 3 dozen twicebright recessed lights (used mostly on interior ceilings so as not to interfere with the house envelope) each with its dedicated electronic transformer. What is the carbon footprint of that? Wouldn’t be better if we had a DC distribution system? It is coming. The data centers with banks of computers have been using this solution for some time. EMerge Alliance – open industry association is developing a 24V standard for DC power distribution in commercial buildings. There is a big push in boating industry for distributed DC electric distribution system that will also save weight by replacing the mechanical fuse boxes with solid state ones. So the future of residential wiring will most likely be two independent wiring systems – a low voltage (24V DC) system for electronic equipment, lighting, and DC powered small appliances and a high voltage (120V AC) system for major appliances but until then we have to deal with the transition headaches.