Passive solar house design is not new. During 9th through 13th century, American Indians built their homes in south facing Pueblo canyon hills that provided them heat from the low winter sun, and cool from high summer sun with natural overhangs. It is a shame that these centuries old best practices are ignored today in new residential construction. Passive solar is different than Passive House – a standard developed in Germany for European climate and adapted to American climate by Passive House Institute US (PHIUS). In our house tours, we got to see one Passive House design, and a number of passive solar designs. Passive House design with super thick walls and small windows looked like a bunker to us – not our cup of tea. In contrast to a Passive House that needs to limit the intake of winter sun because of over heating due to super insulation, passive solar welcomes the winter sun’s warmth, stores it for night time use, treats our winter blues with sunlight, and lets us enjoy the scenery outside.

If you are interested in passive solar home design, “The Solar House: Passive Heating and Cooling” by Daniel Chiras is a must read. After researching passive solar design in Building Science, Green Building Advisor, Mother Nature Network, Zero Energy House, I dived into The Solar House by Chiras. Passive solar has a pretty straightforward set of high level rules. You need large south facing windows (north facing in the southern hemisphere) with high Solar Heat Gain Coefficient (SHGC), a thermal mass to store the sun’s heat, and overhangs to block summer sun on the south facing glazing while letting winter sun in. Of course, you still need a professional to design the system as there are several intricate nuances (e.g. different SHGC ratings of south, east, west and north facing windows, backup heat system sizing, air quality in a super tight house shell, etc.) in passive solar design but that shouldn’t prevent you learning more about it to become a more knowledgeable homeowner, and better yet an evangelist.

The US Federal government in its infinite wisdom gives tax credit to energy efficient windows with U-factor 0.30 or lower, which is fine, and SHGC 0.30 or lower, which is not fine. U-factor is the reciprocal of the area weighted sum of R-values for the various window components (e.g. glazing, frame, etc.). So the smaller the U-factor, the better the window keeps the inside hot, or cold air in. SHGC represents the fraction of the solar energy that the window passes through to heat the house. So a window with an SHGC of 0.30 based on Federal guidelines block 70% of the sun’s energy that can be used to heat the house. That may be a great design objective for hot climates like Florida but for cold climates like Maine, windows with SHGC 0.55 or higher is the desired target. Given the one size fits all standard in US, you need to shop for Canadian, or European windows if you want passive solar. More on that at a later post.

- Perimeter slab insulation

- Stego wrap vapor barrier

- XPS slab insulation, Crete-Heat insulated floor panel, Uponor radiant heat tubing

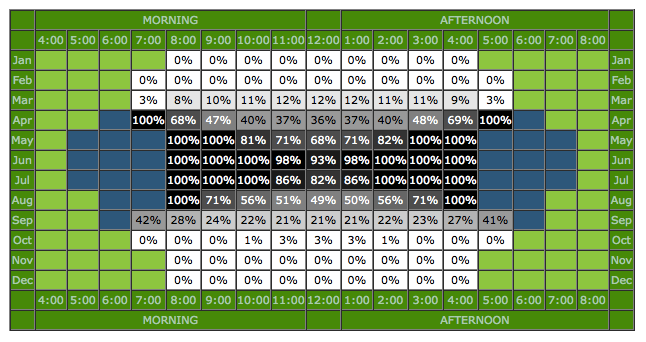

In passive solar design, if the south-facing glass is less than 7% of the floor area, then thermal mass is not needed as building mass in framing, drywall, etc. is sufficient to absorb the solar gain but you won’t be getting passive solar heating after sunset. South facing wall of glass in our Schematic Design dictates thermal mass. In our home, cement slab in the front living area, and secondarily the basement slab serves as thermal mass. As a rule of thumb, for every sq ft of south facing glass area over that 7 percent of total sq ft of the house, you need about 5½ sq ft of 4-inch-thick slab. Overhangs are designed to block out the solar noon on summer solstice (June 21 when the sun is the highest in the sky), and let the solar noon completely in on winter solstice (Dec. 21 when the sun is the lowest in the sky). Our architect specified 4 ft. south facing sunscreens in Design Development. There are on line calculators like the Overhang Design tool by Sustainable Design to design the overhangs with the final size often dictated by compromise. Here is the expected shading performance of our sunscreen design. We’ll get full use of sun’s warmth October through March, and transition in to full shade in April, and out of shade in October.

Spang Builders filled the interior of the foundation below the slab level with gravel, and mechanically compacted. Before pouring the cement for the slab to be used as thermal mass, a vapor barrier is placed at the bottom. Our slab subcontractor used Stego Wrap vapor barrier, and foundation rebar and wire mesh to give strength to the cement. The slab bottom and perimeter is insulated with XPS insulation. Our mechanical design also called for radiant heating so that had be in place before the concrete. Our mechanical designer used Crete-Heat floor panel system with its own insulation and vapor barrier, and Uponor radiant heating. For additional reading, I recommend Designing a Passive Solar Slab that explains the diminishing returns of a slab depth more than 4 inches. More on our mechanical system in a later post.

You don’t have to have an ugly cement slab to go with passive solar. Flatwork craftsman can make a concrete slab look like marble. These folks use a power trowel (sort of like a floating orbital sander with multiple steel trowels rotating at the bottom) to apply a smooth finish to concrete slabs. This process is called burnishing, which produces a shiny, smooth and abrasive resistant hard surface. Burnishing brings a marbleized non-uniform metallic-look to the floor. Our architect/builder team chose S. Richer of Sanford to perform this feat. The results speak for themselves. Our team used a poly backed fabric blanket cover to ensure wet curing over a 28 day period. The blanket ensures that the slab remains wet for the entire curing period.

- Slab before burnishing

- Power trowel

- Slab after burnishing